- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

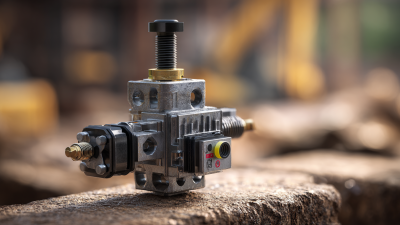

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

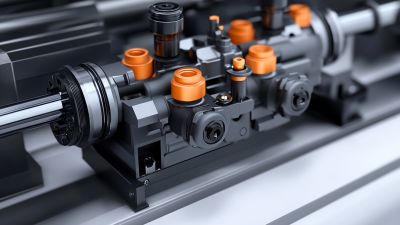

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

5 Reasons Why Directional Control Valves Are Essential for Efficient Hydraulics

In the realm of hydraulics, achieving optimal performance and efficiency is paramount, and one key component that plays a pivotal role in this is the Directional Control Valve. These innovative devices are instrumental in managing the flow of hydraulic fluids, ensuring that power is directed precisely where it’s needed in a hydraulic system. Whether in industrial machinery, construction equipment, or automotive systems, the effectiveness of hydraulic operations largely hinges on the capabilities of Directional Control Valves. In this blog, we will delve into five compelling reasons why these valves are essential for maintaining efficient hydraulic functions, highlighting their benefits, functionality, and the critical role they play in system reliability and performance. Understanding these aspects will not only enhance your knowledge but also empower you to make informed decisions regarding the hydraulic systems you work with.

The Role of Directional Control Valves in Hydraulic System Efficiency

Directional control valves play a pivotal role in enhancing the efficiency of hydraulic systems. They are designed to manage the flow and direction of hydraulic fluids, which is essential for the proper functioning of machinery and equipment. By ensuring that the hydraulic fluid flows only where it’s needed and in the right direction, these valves help to minimize energy losses and reduce unnecessary wear on components. This precision not only enhances the overall performance of hydraulic systems but also contributes to energy savings and sustainability.

Directional control valves play a pivotal role in enhancing the efficiency of hydraulic systems. They are designed to manage the flow and direction of hydraulic fluids, which is essential for the proper functioning of machinery and equipment. By ensuring that the hydraulic fluid flows only where it’s needed and in the right direction, these valves help to minimize energy losses and reduce unnecessary wear on components. This precision not only enhances the overall performance of hydraulic systems but also contributes to energy savings and sustainability.

In the context of modern hydraulic applications, the significance of these valves is further amplified by the need for improved control and responsiveness. Advanced control valve technologies allow for more precise modulation of hydraulic flow, making it possible to optimize machine performance based on varying operational demands. As industries continue to prioritize efficiency and environmental considerations, the integration of high-performing directional control valves becomes essential for developing machines that are energy-efficient and low in emissions. This trend is particularly relevant in fields such as construction, agriculture, and renewable energy, where optimizing hydraulics is crucial for operational success.

Key Statistics Show the Impact of Directional Control Valves on System Performance

Directional control valves play a pivotal role in optimizing hydraulic system performance. According to a report by the International Journal of Advanced Manufacturing Technology, systems equipped with high-efficiency directional control valves can enhance performance by up to 25%, reducing energy consumption and operational costs significantly. Moreover, a survey conducted by the Hydraulic Institute found that 70% of hydraulic failures can be traced back to improper valve selection and integration, underscoring the importance of using the right directional control valves in any hydraulic application.

Tip: When selecting a directional control valve, always consider the duty cycle of your application. Valves that match your operational demands can lead to improved longevity and reduced maintenance costs.

Additionally, a case study published in the Journal of Hydraulic Engineering showed that incorporating advanced directional control valves resulted in a 40% increase in speed and responsiveness for automated systems. This statistic emphasizes how the right valves not only boost efficiency but also enhance the overall productivity of hydraulic systems.

Tip: Regularly monitor the performance of your directional control valves and conduct maintenance checks every six months to prevent unexpected failures and maintain optimal system performance.

How Directional Control Valves Enhance Energy Conservation in Hydraulic Applications

Directional control valves play a pivotal role in enhancing energy conservation within hydraulic applications. By efficiently directing the flow of hydraulic fluid, these valves ensure that power is utilized only when necessary, reducing unnecessary energy consumption. This selective flow control is crucial in systems where precision and efficiency are paramount, allowing operators to activate specific functions while minimizing waste.

In hydraulic fluid power systems used in industries like transportation and heavy machinery, the implementation of directional control valves contributes significantly to overall system efficiency. These valves not only optimize the direction of hydraulic flow but also help in maintaining consistent pressure levels, which is essential for preserving energy. Moreover, they enable quick adjustments to be made in response to varying operational demands, ensuring that energy is used more intelligently and sustainably. The result is a more efficient hydraulic system that meets operational needs while also addressing environmental concerns through reduced energy footprint.

Comparing Traditional and Advanced Directional Control Valves: Which Is Better?

When it comes to hydraulic systems, choosing between traditional and advanced directional control valves can significantly impact efficiency and performance. Traditional valves, while reliable, often lack the adaptability required for modern applications. They may require manual adjustments and are typically less responsive to changing system demands. In contrast, advanced models incorporate smart technology, enabling real-time adjustments and improved responsiveness. This means they can better handle varying fluid pressures and flow rates, optimizing the overall hydraulic performance.

**Tip:** When selecting a directional control valve, consider the specific needs of your application. If your system often requires adjustments, investing in advanced valves with integrated sensors might save time and increase operational efficiency.

Another notable difference lies in maintenance and longevity. Traditional valves may demand more frequent repairs and replacements due to their mechanical nature, while advanced valves often have extended service intervals and self-diagnostic features. Their robust designs can lead to reduced downtime, ensuring your hydraulic machinery operates smoothly.

**Tip:** Always evaluate the total cost of ownership when comparing valve types. While advanced valves might have a higher initial cost, their enhanced durability can result in significant cost savings over time.

5 Reasons Why Directional Control Valves Are Essential for Efficient Hydraulics

This chart compares the efficiency of traditional and advanced directional control valves based on key performance indicators: Flow Rate, Response Time, Pressure Drop, Energy Consumption, and Maintenance Frequency.

Future Trends in Directional Control Valve Technology for Streamlined Hydraulics

The future of directional control valve technology is poised for transformative advancements that will streamline hydraulic systems across various industries. According to a market research report by MarketsandMarkets, the global hydraulic valves market is expected to grow from USD 30.41 billion in 2021 to USD 43.87 billion by 2026, driven primarily by increased automation demands in manufacturing and construction. As a result, the development of smart directional control valves, equipped with IoT capabilities, will emerge as a key trend. These valves are designed to enhance real-time monitoring and data analytics, thus optimizing hydraulic system performance and reducing downtime.

Moreover, the shift towards energy efficiency is prompting the adoption of proportional and servo-controlled directional valves. Research from the Hydraulic Institute indicates that implementing these technologies can improve system efficiency by up to 20%, significantly diminishing energy consumption and operational costs. Innovations in materials and manufacturing processes also contribute to this evolution; for example, lightweight yet durable composite materials can enhance valve responsiveness and lifespan. As industries seek to improve productivity while minimizing their environmental footprint, the integration of advanced directional control valves will undoubtedly play a critical role in shaping the future of hydraulic technology.

5 Reasons Why Directional Control Valves Are Essential for Efficient Hydraulics - Future Trends in Directional Control Valve Technology for Streamlined Hydraulics

| Feature | Importance | Current Trends | Future Developments |

|---|---|---|---|

| Precision Control | Ensures accurate flow direction and speed. | Increased use of digital control systems. | Integration with IoT for real-time monitoring. |

| Energy Efficiency | Reduces energy consumption in hydraulic systems. | Use of variable displacement technology. | Advanced valves that optimize performance automatically. |

| Durability | Resists wear and prolongs system life. | Enhanced materials for better stress resistance. | Smart materials that adapt to environmental changes. |

| Safety Mechanisms | Prevents system failure and hydraulic accidents. | Improved locking and emergency shut-off features. | AI-driven predictive maintenance alerts. |

| Versatility | Applicable in various hydraulic applications. | Modular designs for easy configuration changes. | Customizable solutions for specialized tasks. |

Related Posts

-

5 Key Advantages of Using Directional Control Valves for Enhanced Hydraulic Efficiency in 2023

-

Top Strategies for Optimizing Your Best Directional Control Valve Performance

-

Top 10 Directional Control Valve Manufacturers from China Featured at the 137th Canton Fair

-

Navigating the 2025 Technology Trends in Industrial Hoses for Optimal Performance and Efficiency

-

7 Innovative Uses for Hydraulic Hoses in Industrial Applications

-

How to Optimize Your Pump Valve Selection for Maximum Efficiency

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry