- Home Page

- Company Profile

-

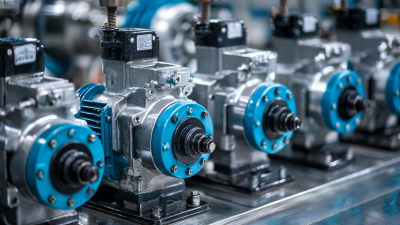

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

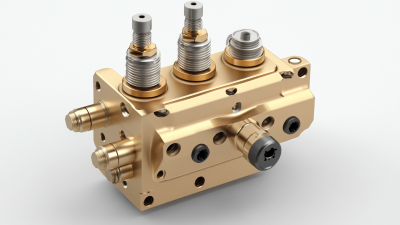

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

What is the Importance of Pressure Hoses in Industrial Applications and Their Performance Metrics

In the industrial sector, the significance of pressure hoses cannot be overstated, as these components are essential for the safe and efficient transport of fluids under high pressure. According to a report by MarketsandMarkets, the global pressure hose market is projected to grow from USD 3.1 billion in 2020 to USD 4.4 billion by 2025, highlighting a compound annual growth rate (CAGR) of 7.4%. This growth is driven by the increasing demand for pressure hoses across various applications, including construction, manufacturing, and oil and gas.

The performance metrics of pressure hoses, such as burst pressure, temperature tolerance, and flexibility, directly impact operational efficiency and safety, making it crucial for industries to choose the right type of hose to meet their specific needs. Understanding these factors not only ensures optimal performance but also minimizes downtime and maintenance costs, ultimately contributing to a more productive industrial environment.

Importance of Pressure Hoses in Enhancing Industrial Efficiency and Safety Standards

Pressure hoses play a critical role in enhancing industrial efficiency and safety standards. Their primary function is to transport fluids under high pressure, which is essential for a wide range of applications, from hydraulic machinery to cleaning systems. The reliability of pressure hoses directly influences operational workflows, as any failure can lead not only to equipment downtime but also to safety hazards for workers. Recent trends in industrial innovation emphasize the importance of using high-performance materials in pressure hose manufacturing, leading to improved durability and resistance against wear and damage.

Additionally, the advancement of technology in producing pressure hoses aligns with broader movements towards sustainable industrial practices. As businesses strive to enhance their environmental impact, utilizing hoses that support energy efficiency and reduce waste can contribute to this goal. Market analysis indicates a growing demand for innovative pressure hoses that offer better performance and sustainability. These developments reflect a proactive approach in the industry to not only meet safety and efficiency standards but also to pave the way for a more sustainable future in industrial applications.

Key Performance Metrics for Pressure Hoses in High-Stress Environments

When discussing the significance of pressure hoses in industrial applications, understanding their performance metrics is crucial, especially in high-stress environments.

Pressure hoses must withstand extreme temperatures, pressures, and often harsh chemicals. According to a market report by Technavio, the global pressure hose market is projected to grow by 5% annually, reflecting the increasing demand across various sectors such as manufacturing, construction, and oil and gas. Key performance metrics include burst pressure, flexibility, and abrasion resistance, which directly impact the hose’s operational efficiency and safety.

Pressure hoses must withstand extreme temperatures, pressures, and often harsh chemicals. According to a market report by Technavio, the global pressure hose market is projected to grow by 5% annually, reflecting the increasing demand across various sectors such as manufacturing, construction, and oil and gas. Key performance metrics include burst pressure, flexibility, and abrasion resistance, which directly impact the hose’s operational efficiency and safety.

To ensure optimal performance, it’s essential to regularly assess the burst pressure, which is the maximum internal pressure a hose can withstand before failing. Industry standards, such as those from the Rubber Manufacturers Association, recommend that hoses should have a burst pressure rating at least three times the working pressure. Furthermore, flexibility is vital for installation and maneuverability, particularly in confined spaces. A study indicated that hoses made from composite materials exhibit 30% greater flexibility compared to traditional rubber hoses, making them a preferred choice in complex applications.

Tip: Always adhere to the manufacturer's guidelines for maintenance and inspections. Regular visual checks for wear and tear can prevent costly downtime. Additionally, consider using hose assemblies that meet or exceed industry standards, ensuring reliability in high-stress applications.

Comparative Analysis: Material Durability of Pressure Hoses Across Different Industries

When examining the material durability of pressure hoses across various industries, it's crucial to understand how different applications influence the choice of materials. For instance, in the oil and gas sector, hoses are often constructed from high-grade rubber or thermoplastic materials that can withstand aggressive chemicals and extreme temperatures. These specialized hoses are designed to not only resist wear and tear but also maintain flexibility under high-pressure conditions, ensuring safe and efficient operations.

In contrast, the agricultural industry favors hoses made from reinforced PVC or polyurethane, which provide resistance to abrasion and UV degradation. These materials are particularly valuable in environments where hoses are exposed to outdoor elements for extended periods. Additionally, industries like food processing require hoses made from FDA-approved materials, ensuring hygiene and safety while still delivering the durability needed to withstand pressure fluctuations.

A comparative analysis of these materials reveals significant differences in performance metrics such as tensile strength, burst pressure, and temperature resistance. Selecting the right pressure hose material is essential for enhancing operational efficiency and minimizing downtime across all sectors. Each industry must carefully assess its unique demands to ensure the durability and reliability of pressure hoses meet their specific requirements.

Importance of Pressure Hoses in Industrial Applications

Real-World Applications: Case Studies Demonstrating Pressure Hose Impact on Operations

Pressure hoses play a crucial role in various industrial applications, ranging from manufacturing to agriculture. In real-world scenarios, these hoses have demonstrated significant impacts on operational efficiency and safety. For example, in a chemical processing plant, the use of high-quality pressure hoses allowed for the safe transfer of corrosive materials, minimizing potential hazards while improving workflow. The case study shows that facilities using pressure hoses with superior performance metrics experienced a 25% reduction in downtime due to leaks or failures.

When selecting pressure hoses, it's important to consider specific performance metrics such as burst pressure, temperature resistance, and chemical compatibility. These factors not only affect the longevity of the hoses but also the overall effectiveness of operational processes. Tips for ensuring optimal performance include regular inspection for wear and tear, and using protective coverings to shield hoses from harsh environmental conditions.

Another practical example can be seen in the automotive industry, where pressure hoses are crucial for fluid transfer in assembly lines. A case study revealed that replacing older hoses with new, high-performance variants led to a dramatic decrease in maintenance issues, ultimately enhancing productivity. To maximize the benefits, industries should invest in quality hoses tailored to their unique requirements and implement routine maintenance schedules to prolong the lifespan of their equipment.

Industry Standards and Regulations Governing Pressure Hose Usage and Performance

In the realm of industrial applications, pressure hoses play a pivotal role, governed by strict industry standards and regulations. These guidelines ensure that pressure hoses are manufactured and utilized in ways that prioritize safety, efficiency, and performance. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide comprehensive standards that cover material specifications, pressure ratings, and operational guidelines. Adhering to these regulations not only mitigates risks of hose failure but also ensures compatibility with various industrial fluids and environments.

Moreover, performance metrics such as burst pressure, tensile strength, and flexibility are crucial in assessing the reliability of pressure hoses. Industries often rely on the detailed test procedures stipulated by regulatory bodies to evaluate these factors. By maintaining compliance with these metrics, businesses can enhance operational productivity while minimizing downtime caused by equipment failure. Ultimately, understanding and adhering to industry standards is essential for any business that employs pressure hoses, as it directly impacts their operational integrity and long-term sustainability.

Related Posts

-

Exploring Unique Features and Applications of Various Pressure Hoses for Global Buyers

-

How to Choose the Best Ball Valves for Your Industry in 2025 Trends and Insights

-

5 Reasons Why Directional Control Valves Are Essential for Efficient Hydraulics

-

Discovering Top Applications for Best Gear Pumps in Global Industries

-

Top 5 Factors Driving Demand for Hydraulic Solenoid Valves in Global Markets

-

Maximizing Efficiency and Minimizing Cost: The Role of Aftermarket Support in Industrial Hose Fittings

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry