- Home Page

- Company Profile

-

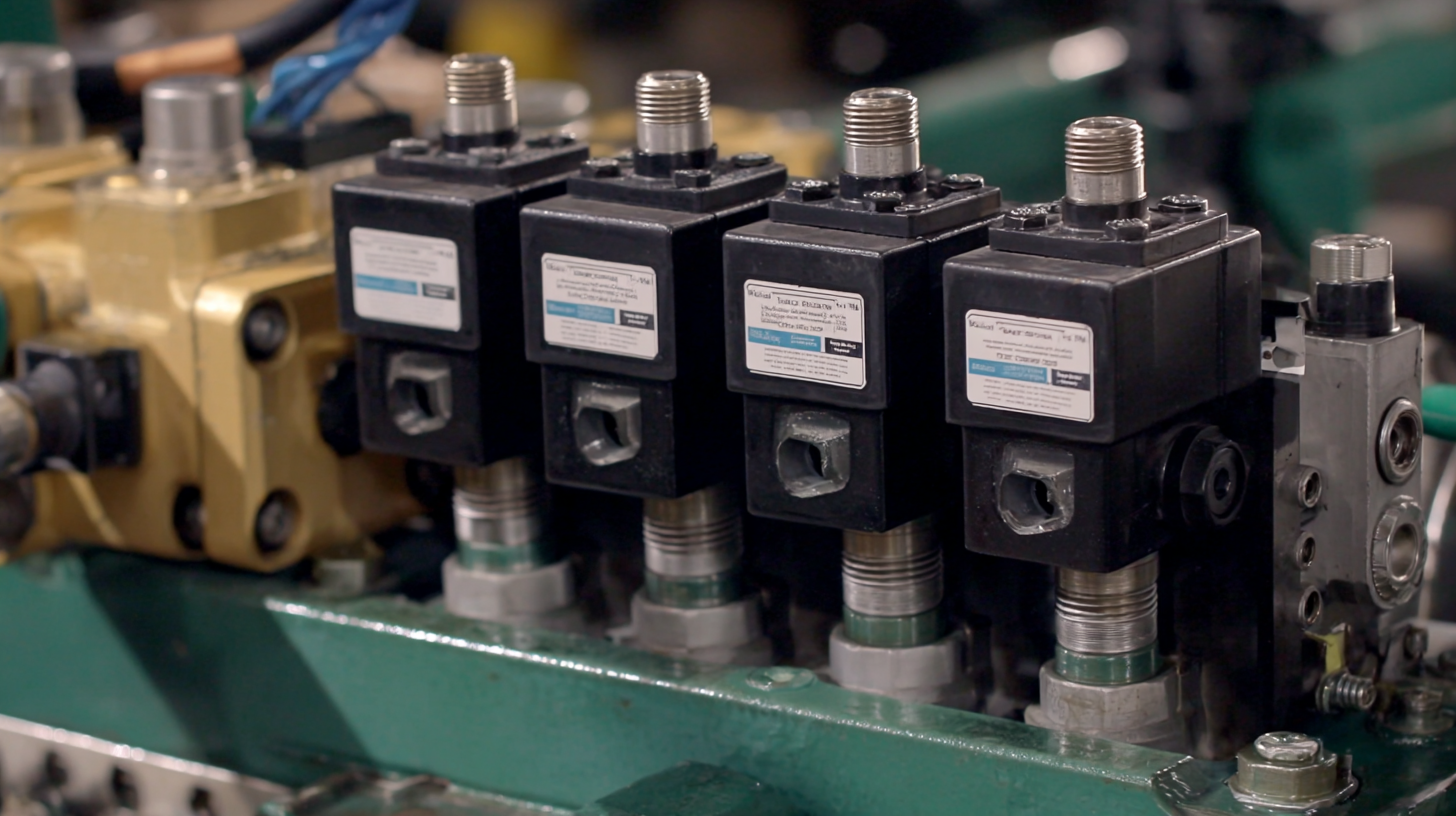

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Maximizing Your Savings How After Sales Support Reduces Maintenance Costs for Best Hydraulic Valves

In the ever-evolving world of industrial machinery, hydraulic valves play a crucial role in ensuring efficient operation and system reliability. According to a recent report by Research And Markets, the global hydraulic valves market is projected to reach $6.87 billion by 2026, growing at a CAGR of 5.7% from 2021 to 2026. This growth highlights the increasing demand for high-performance hydraulic systems across various industries. However, the initial investment in high-quality hydraulic valves can be overshadowed by the ongoing maintenance costs that often arise from inadequate after-sales support.

Effective after-sales service not only enhances the longevity of hydraulic valves but also significantly reduces overall maintenance expenses. By understanding and optimizing these support systems, businesses can maintain operational efficiency while maximizing their savings, making it essential to explore industry application cases that illustrate these benefits.

Understanding After Sales Support and Its Impact on Maintenance Costs

After sales support plays a pivotal role in reducing maintenance costs for hydraulic valves, a crucial component in various industrial applications. According to a report by the International Society for Automation, proper maintenance can prolong the life of hydraulic systems by up to 50%. This highlights the importance of robust after sales service, which includes timely technical assistance, comprehensive training, and readily available spare parts. Companies that invest in after sales support see a significant reduction in unexpected downtime—up to 30%, as stated in a study by Machinery Maintenance Magazine.

Furthermore, after sales support enhances the understanding of optimal operation practices among end-users. According to a survey conducted by the Fluid Power Journal, companies with effective training programs reported a 20% decrease in maintenance costs compared to those without. This training allows operators to identify potential issues early, minimizing the need for costly repairs and extending the lifespan of hydraulic valves. Thus, prioritizing after sales support not only optimizes performance but also translates to tangible financial savings for businesses in the long run.

Key Benefits of Quality Hydraulic Valves in Long-Term Savings

Investing in quality hydraulic valves not only enhances the performance of machinery but also contributes significantly to long-term savings through reduced maintenance costs. According to a recent industry report, high-quality hydraulic systems can lower maintenance expenses by up to 30% over their lifespan. This reduction stems from fewer breakdowns and the enhanced reliability of superior components, which directly translates into less downtime and repair costs.

Furthermore, as industries increasingly transition to all-electric systems, the integration of intelligent technologies into hydraulic applications can further optimize operational efficiency. These all-electric subsea systems are designed to provide real-time data and analytics, enabling operators to anticipate maintenance needs proactively. Research indicates that predictive maintenance strategies enabled by such intelligent systems can lead to cost reductions of 20-25%. By investing in advanced hydraulic valves and support systems that incorporate smart technology, businesses can not only maximize their savings but also ensure their operations run smoothly and efficiently for years to come.

Maximizing Your Savings: How After Sales Support Reduces Maintenance Costs for Best Hydraulic Valves - Key Benefits of Quality Hydraulic Valves in Long-Term Savings

| Feature | Benefit | Estimated Annual Savings ($) | Maintenance Cost Reduction (%) |

|---|---|---|---|

| High Durability | Less Frequent Replacements | $1,500 | 30% |

| After Sales Support | Quick Issue Resolution | $1,000 | 20% |

| Energy Efficiency | Reduced Energy Costs | $800 | 15% |

| Quality Materials | Increased Reliability | $1,200 | 25% |

| Advanced Technology | Improved Performance | $900 | 18% |

Best Practices for Engaging with After Sales Support for Optimal Performance

Engaging effectively with after sales support is crucial for maintaining the optimal performance of hydraulic valves. One of the best practices to consider is establishing a clear line of communication with your support team. This involves not only reporting issues but also discussing preventive measures and maintenance schedules. A proactive approach allows you to identify potential problems before they escalate, thus significantly reducing unexpected downtime and costly repairs.

Another important strategy is to utilize the resources that after sales support provides, such as training sessions and technical documentation. By equipping your team with the knowledge and skills to operate and troubleshoot hydraulic valves efficiently, you enhance their productivity and reduce error rates. Additionally, keeping an open channel for regular feedback can lead to continuous improvements in both your operations and the products, fostering a more collaborative relationship with the manufacturer. Engaging with after sales support in these ways ultimately contributes to long-term savings and impactful performance outcomes.

Comparing Cost Structures: Maintenance with vs. without After Sales Support

When it comes to maintaining hydraulic valves, the cost structure significantly changes based on whether you have after-sales support or not. Companies that invest in after-sales services often experience lower maintenance costs because they receive ongoing guidance and resources. This support typically includes regular inspections, troubleshooting help, and prompt access to replacement parts, which prevent larger issues from developing over time.

When it comes to maintaining hydraulic valves, the cost structure significantly changes based on whether you have after-sales support or not. Companies that invest in after-sales services often experience lower maintenance costs because they receive ongoing guidance and resources. This support typically includes regular inspections, troubleshooting help, and prompt access to replacement parts, which prevent larger issues from developing over time.

Tip 1: Prioritize vendors who offer comprehensive after-sales support packages. A little extra upfront investment can lead to substantial savings down the line through reduced downtime and enhanced efficiency.

Conversely, those who opt for a DIY maintenance approach can face unexpected expenses and delays. Without expert assistance, businesses may struggle to diagnose problems accurately or source the right parts, leading to prolonged downtime and increased labor costs.

Tip 2: Incorporate a maintenance schedule that leverages after-sales support to regularly assess the performance of your hydraulic valves, ensuring you address wear and tear before it escalates into costly repairs.

Real-World Examples of Savings Through Effective After Sales Strategies

In today's competitive hydraulic valve market, effective after-sales support is crucial for maximizing savings and minimizing maintenance costs. A recent study by the International Journal of Hydraulic Engineering revealed that proper after-sales strategies can reduce maintenance expenses by up to 30% over a valve's lifespan. Companies that prioritize customer support and proactive maintenance programs see a significant return on investment, maintaining operational efficiency while minimizing downtime.

One real-world example is a leading hydraulic manufacturer that implemented a robust training program for their clients. By educating users on optimal valve operation and preventative maintenance, they observed a significant decrease in wear and tear, leading to a 25% reduction in overall service costs. This approach not only maximized the hydraulic systems' longevity but also fostered customer loyalty through enhanced satisfaction.

Tip 1: Regularly schedule maintenance check-ups to identify wear early—this is essential to prolonging the life of your hydraulic valves.

Tip 2: Invest in user training sessions that focus on the best operational practices for your hydraulic systems to avoid common pitfalls that can lead to costly repairs.

By implementing these strategies, companies can leverage after-sales support to significantly reduce maintenance costs while expanding the durability and reliability of their hydraulic valves.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry