- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

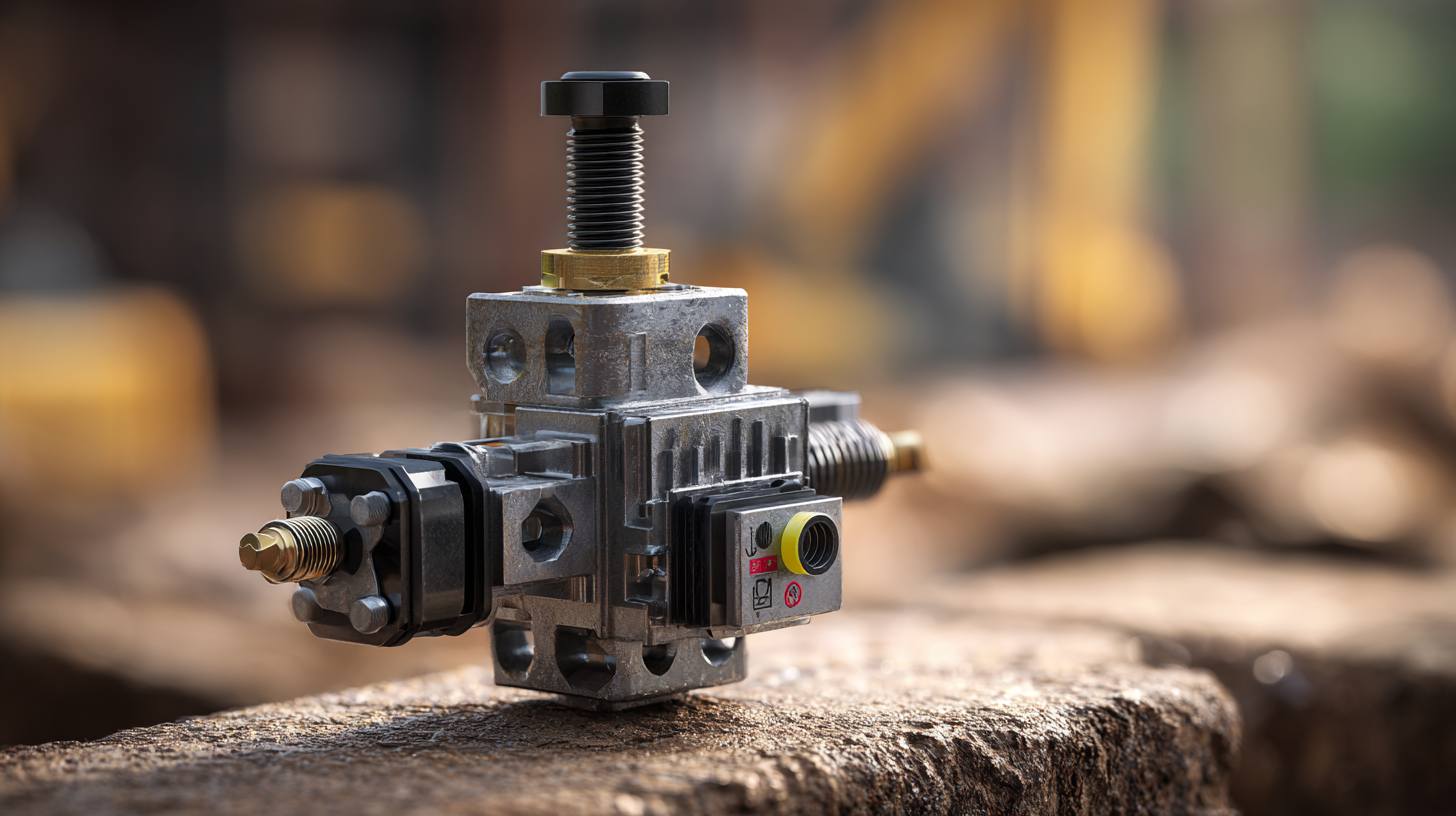

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Top Strategies for Optimizing Your Best Directional Control Valve Performance

Directional Control Valve performance is critical in hydraulic and pneumatic systems, influencing the efficiency and responsiveness of various applications. According to a recent market report by ResearchAndMarkets, the global market for Directional Control Valves is expected to grow at a CAGR of 5.2% from 2021 to 2026, highlighting the increasing importance of optimizing these components in industrial machinery. As manufacturers seek to enhance system reliability and operational efficiency, understanding the best strategies for improving Directional Control Valve performance becomes essential.

This blog will explore key optimization techniques that can significantly impact system functionality and longevity, ensuring that engineers and technicians are equipped with the knowledge to maximize the potential of their Directional Control Valves.

Identifying Key Qualities in Top Directional Control Valve Suppliers for Optimal Performance

When selecting a directional control valve supplier for optimal performance, it is crucial to focus on several key qualities. First and foremost, the supplier's experience in the industry can significantly impact the quality and reliability of their products. An established supplier will have a deeper understanding of various applications and the specific requirements that come with them. Look for suppliers with a proven track record in manufacturing high-quality valves that meet stringent industry standards, as this often correlates with enhanced performance and durability.

Additionally, a reputable supplier should offer exceptional customer support and technical expertise. The ability to provide guidance on product selection, installation, and troubleshooting can make a significant difference in achieving optimal valve performance. Suppliers that invest in ongoing training and resources for their staff are likely more equipped to address customer needs effectively. Furthermore, consider their ability to customize solutions, as tailored products can often lead to improved efficiency and service life in specialized applications.

Understanding the Role of Material Selection in Directional Control Valve Reliability

Material selection plays a crucial role in ensuring the reliability of directional control valves. These valves operate under various conditions, including high pressure, temperature fluctuations, and exposure to corrosive substances. Choosing the right materials not only impacts the valve's performance but also its longevity and maintenance requirements. For instance, stainless steel and brass are commonly used for their corrosion resistance and strength, making them ideal for applications in harsh environments.

In addition to corrosion resistance, the thermal and mechanical properties of the materials must be considered. High-performance polymers, such as PTFE, can enhance sealing capabilities and reduce wear. When selecting materials, engineers must evaluate the specific application and operating conditions of the valve. By understanding the relationship between material properties and their application, manufacturers can produce more reliable directional control valves that require less frequent maintenance and reduce downtime. This strategic approach to material selection ultimately leads to improved system efficiency and performance.

Top Strategies for Optimizing Your Best Directional Control Valve Performance

This chart illustrates the relationship between material selection and the reliability of directional control valves. The data points reflect the performance ratings based on different materials used in the manufacturing process.

Analyzing the Impact of Regular Maintenance on Directional Control Valve Efficiency

Regular maintenance of directional control valves is crucial for optimizing their efficiency and prolonging their lifespan. A well-maintained control valve ensures smooth operation and accurate flow regulation, significantly impacting overall system performance. When maintenance routines are neglected, valves can become sluggish, leading to fluctuations in pressure and flow that can disrupt entire hydraulic systems. Therefore, implementing a proactive maintenance schedule can help identify potential issues early, reducing downtime and enhancing reliability.

Moreover, the efficiency of directional control valves can be greatly improved through simple yet effective maintenance practices. For example, regular inspections to check for leaks, wear, and debris can prevent costly repairs and enhance the responsiveness of the valve. Cleanliness plays a pivotal role in maintaining optimal functionality; ensuring that systems are free from contaminants will lead to less wear and tear on valve components. Emphasizing these maintenance strategies not only boosts valve performance but also contributes to the energy efficiency of the entire hydraulic system, which is increasingly essential in modern applications.

Top Strategies for Optimizing Your Best Directional Control Valve Performance - Analyzing the Impact of Regular Maintenance on Directional Control Valve Efficiency

| Maintenance Strategy | Impact on Efficiency (%) | Maintenance Frequency (Months) | Common Issues Addressed |

|---|---|---|---|

| Regular Inspection | 15 | 3 | Leaks, Contamination |

| Fluid Replacement | 20 | 6 | Viscosity, Contamination |

| Seal Replacement | 25 | 12 | Worn Seals, Leaks |

| Component Lubrication | 30 | 4 | Friction, Wear |

| Calibration | 10 | 12 | Pressure Variance |

Evaluating the Importance of Technical Support from Suppliers for Valve Performance

Technical support from suppliers is crucial for optimizing the performance of directional control valves. In the fluid power industry, approximately 70% of valve malfunctions can be traced back to improper installation or maintenance, as highlighted in a recent report by the International Fluid Power Society (IFPS). This underscores the need for robust technical assistance from suppliers, who can provide guidance on proper setup and adaptation to specific operational conditions. Such support ensures that the directional control valves are tailored to meet the unique demands of different applications, maximizing both efficiency and longevity.

Furthermore, a survey conducted by the National Fluid Power Association (NFPA) revealed that companies that regularly utilize supplier technical support experience a 30% reduction in downtime due to valve-related issues. The expertise supplied by manufacturers can aid in troubleshooting, helping organizations quickly identify and rectify problems before they escalate into more significant failures. This pivotal relationship not only fosters better valve performance but also enhances overall system reliability, making technical support a vital element in the strategic management of fluid control systems.

Leveraging Industry Data to Guide Supplier Selection for Maximized Valve Functionality

When selecting a supplier for directional control valves, leveraging industry data is crucial for ensuring optimal valve functionality. Industry data encompasses performance metrics, reliability statistics, and customer feedback that provide insights into the effectiveness of various suppliers. By analyzing this data, businesses can identify trends and make informed decisions that enhance performance. For instance, understanding which suppliers have the best track record for maintaining valve integrity over time allows companies to prioritize partnerships that will lead to fewer operational disruptions.

Moreover, incorporating technical specifications and compatibility information into the selection process can further streamline the optimization of valve performance. This ensures that the chosen valves not only meet operational requirements but also integrate seamlessly into existing systems. Access to comprehensive data helps evaluate how different valves will perform under specific operating conditions, thus guiding procurement strategies that maximize efficiency and reduce maintenance costs. By prioritizing data-driven supplier selection, businesses can ultimately enhance their directional control valve performance and achieve greater operational success.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry